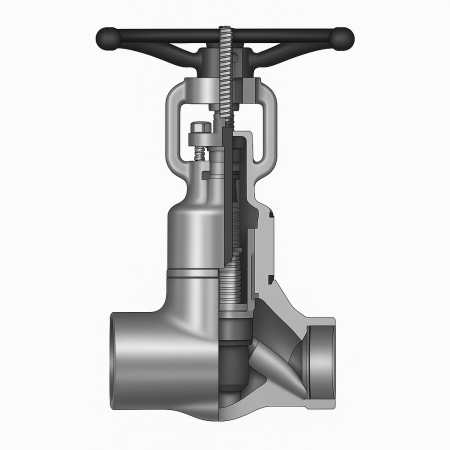

Bellow Seal Valves - ANSI

The fluids in pipelines are often toxic, radioactive, and hazardous to health, making it essential to protect the atmosphere from these chemicals under all circumstances. For this purpose, the bellows system is indispensable, as it completely seals and isolates the stem. Additionally, the upper and lower parts are fully welded using weld seams, ensuring the valve is completely leak-tight. Since the bellows can move axially up to 2025% of its free length, the service life is significantly extended. A helium leak test and PMI (Positive Material Identification) tests can be provided upon request.

Key Features of Bellow Seals

Bellow seals provide complete tightness through a fully isolated stem and welded body components—ideal for handling toxic, radioactive, or hazardous media. The axially flexible bellows significantly extends service life, and optional tests such as helium leak testing or PMI (Positive Material Identification) ensure the highest safety standards.

Absolute tightness thanks to fully welded construction

The bellows system fully isolates the stem and welds the upper and lower parts gas-tight—ideal for the safe handling of toxic, radioactive, or hazardous media.

Longer service life thanks to flexible axial movement

The bellows can move axially up to 2025% of its free length, minimizing material fatigue and significantly increasing the service life of the valve.

Maximum safety thanks to optional testing procedures

Optional helium leak tests and PMI material inspections ensure maximum operational safety—even for critical industrial applications.

Bellow Seal Gate Valve & Bellow Seal Globe Valves (Faltenbalg-Absperrschieber und Faltenbalg-Absperrventile)

Datenblätter

Größe: 1/4“ bis 3“

LBS: 150, 300, 600, 800, 1500

Gehäuse: A105 N, LF2, F304, F316, F316L, F316ti, F321, 1.4404, 1.1138, 1.4308, 1.5419, 1.7357, 1.7379, CF8M, CF3M, CF3, WC1, WC6, WC9, LCB

Description of our Bellow Seals:

Bellow Seal valves effectively prevent leaks and are especially efficient in terms of heat loss. The “bellow” is generally made of stainless steel. Additionally, these valves can be ordered with a regulating cone or throttling cone. The face-to-face dimension complies with ASME B16.10. The valves come with a declaration of conformity and CE marking according to DGRL 97/23/EG. Connections are available as flanged ends (ASME B16.5) and butt weld ends (BW ASME B16.25).

- Depending on the material selection, the shut-off valves are suitable for water, steam, oil, gas, or other aggressive media.

- Special coatings available according to customer requirements.

- TA-Luft compliance according to VDI 2440.

- Stellite-coated versions (STELLITE) available.