Globe Valves nach ANSI

Globe Valves sind vom Gate Valve zu unterscheiden. Beide sind für das Öffnen und Schließen der Rohrleitung verantworlich, jedoch können Globe Valves mit einem Regulierkegel (Drosselkegel/Regulation Disc) ausgestattet werden. Hierdurch kann der Flüssigkeitsstrom ganz einfach und je nach belieben geregelt werden. Ein weiterer Unterschied der beiden Armaturen besteht darin, dass Gate Valves einen vollen Durchgang haben. Dieser ist bei den Globe Valves nicht vorhanden.

Die wichtigsten Eigenschaften von Globe Valves

Globe Valves sind Regelarmaturen zur präzisen Steuerung oder Absperrung von Flüssigkeiten und ermöglichen dank Handradbedienung auch Wartungsarbeiten; optional sorgt ein By-Pass-Ventil für einfachen Druckausgleich. Im Vergleich zu Gate Valves bieten sie eine feinere Durchflussregelung und eignen sich ideal für Anwendungen mit kontrolliertem Medienstrom.

Präzise Durchflussregelung

Globe Valves ermöglichen durch ihre spezielle Kegelkonstruktion eine exakte Steuerung des Medienflusses – ideal für Anwendungen, bei denen der Durchfluss nicht nur unterbrochen, sondern fein geregelt werden muss.

Präzise Durchflussregelung

Mit integrierter Rückdichtung (Back Seat) und optionaler Stellit-Aufpanzerung sind Globe Valves langlebig, wartungsfreundlich und auch bei hohen Drücken und Temperaturen zuverlässig einsetzbar.

Präzise Durchflussregelung

Ein optional erhältliches By-Pass-Ventil sorgt für Druckausgleich vor der Betätigung und erleichtert damit das Öffnen und Schließen – besonders bei hohen Betriebsdrücken ein spürbarer Komfortgewinn.

Häger Globe Valve nach ANSI Norm

Datenblätter

Hier gelangen Sie zu Absperrventile (Globe Valve) nach DIN Norm

Größe: 2“ bis 24“

LBS: 150, 300, 600, 900, 1500, 2500

Gehäuse: 1.0619, A216 WCB, 1.4408, 1.4306, 1.4404, 1.1138, 1.4308, 1.5419, 1.7357, 1.7379, CF8M, CF3M, CF3, WC1 WC6, WC9, LCB, LCC

Beschreibung zu unseren Globe Valves:

- Regulierkegel / Drosselkegel (Regulating Disc)

- Baulänge nach ASME B16.10

- Konformitätserklärung und CE-Kennzeichnung nach DGRL97/23/EG

- Flanschausführung (ANSI B16.5) & Schweißenden wählbar.

- Optional mit TA-LUFT (Technische Anleitung zur Reinhaltung der Luft – TA Luft) Systeme nach VDI 2440

- Je nach Werkstoffwahl sind die Absperrventile für Wasser, Dampf, Öl, GAS oder sonstige aggressive Medien geeignet.

- ISO – TOP Flansch (zum Aufbau eines Antriebes)

- Antrieb –> pneumatisch, elektrisch, hydraulisch, Gas über Öl oder per Getriebe & Handrad

- Isolieraufsatz / Spindelverlängerung

- Sonderlackierung gemäß Kundenanforderung

- TA – LUFT nach VDI 2440

- Stellitierte Ausführungen (STELLITE)

- Emissions-Leaktest nach EN ISO 15848-2 B

- Betriebs.-u. Wartungsanleitungen der Absperrschieber können in verschiedenen Landessprachen zur Verfügung gestellt werden.

- EAC TR –TS Konformitätsdeklarationen der Zollunion auftragsunabhängig für den Export und Einsatz der Produkte in der Russischen Föderation, Weißrussland oder Kasachstan (EAC), Gültigkeit 1, 3 oder 5 Jahre. EAC GOST TR TS 010/2011 (Machinery directive) oder EAC GOST TR TS 032/2013 für Armaturen größer und inkl. DN25

- Armaturenpass TP nach GOST 2.601 – 2006

- TÜV Abnahmen (3.2)

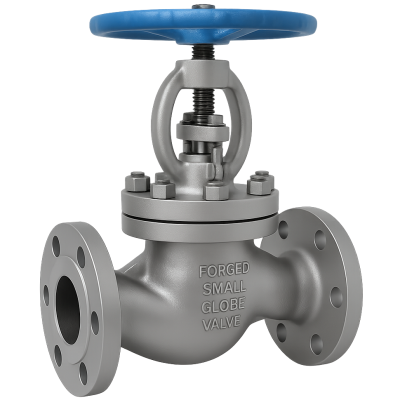

Globe Valve (Forged Small, Flanged Ends)

Datenblätter

Hier finden Sie Absperrventile (Globe Valve) nach DIN Norm

Größe: 1/2“ bis 2-1/2“

LBS: 150, 300, 600, 900, 1500, 2500

Gehäuse: A105N, F304, F316, F321, F316ti, F5, F12, F22

Beschreibung zu unseren Globe Valves:

- Baulänge nach ASME B16.10

- Armaturen größer 1“ mit Konformitätserklärung und CE-Kennzeichnung nach DGRL97/23/EG

- Flanschausführung

- Optional TA-LUFT (Technische Anleitung zur Reinhaltung der Luft – TA Luft) Systeme nach VDI 2440 bestellbar.

- Die Armaturen in Flanschausführung sind Integral geschmiedet!

- Disc auch als Regulating Disc erhältlich

- STELLITIERTE Ausführung optional

- Je nach Werkstoffwahl sind die Globe Valves für Wasser, Dampf, Öl, GAS oder sonstige aggressive Medien geeignet.

- ISO – TOP Flansch (zum Aufbau eines Antriebes)

- Isolieraufsatz / Spindelverlängerung

- Sonderlackierung gemäß Kundenanforderung

- TA – LUFT nach VDI 2440 | optional

- Emissions-Leaktest nach EN ISO 15848-2 B

- Betriebs.-u. Wartungsanleitungen der Absperrschieber können in verschiedenen Landessprachen zur Verfügung gestellt werden.

- EAC TR –TS Konformitätsdeklarationen der Zollunion auftragsunabhängig für den Export und Einsatz der Produkte in der Russischen Föderation, Weißrussland oder Kasachstan (EAC), Gültigkeit 1, 3 oder 5 Jahre. EAC GOST TR TS 010/2011 (Machinery directive) oder EAC GOST TR TS 032/2013 für Armaturen größer und inkl. DN25

- Armaturenpass TP nach GOST 2.601 – 2006

- TÜV Abnahmen (3.2)

Globe Valve (Forged Small)

Datenblätter

Größe: 1/4“ bis 2-1/2“

LBS: 800, 1500, 2500

Gehäuse: A105N, F304, F316, F321, F316ti, F5, F12, F22

Beschreibung zu unseren Globe Valves:

- BW WELD ASME B16.25 , SW WELD ASME B16.11 , SCREWED ENDS ASME B1.20.1

- Armaturen größer 1“ mit Konformitätserklärung und CE-Kennzeichnung nach DGRL97/23/EG

- Verschraubter Deckel, außenliegende Spindel und Betätigung per Handrad.

- Disc / ebenfalls mit Regulating Disc erhältlich

- STELLITIERTE Ausführung optional

- Je nach Werkstoffwahl sind die Kleinschieber / Absperrschieber für Wasser, Dampf, Öl, GAS oder sonstige aggressive Medien geeignet.

- ISO – TOP Flansch (zum Aufbau eines Antriebes)

- Isolieraufsatz / Spindelverlängerung

- Sonderlackierung gemäß Kundenanforderung

- TA – LUFT nach VDI 2440 | optional

- Emissions-Leaktest nach EN ISO 15848-2 B

- Betriebs.-u. Wartungsanleitungen der Absperrschieber können in verschiedenen Landessprachen zur Verfügung gestellt werden.

- EAC TR –TS Konformitätsdeklarationen der Zollunion auftragsunabhängig für den Export und Einsatz der Produkte in der Russischen Föderation, Weißrussland oder Kasachstan (EAC), Gültigkeit 1, 3 oder 5 Jahre. EAC GOST TR TS 010/2011 (Machinery directive) oder EAC GOST TR TS 032/2013 für Armaturen größer und inkl. DN25

- Armaturenpass TP nach GOST 2.601 – 2006

- TÜV Abnahmen (3.2)

Industrie – Forged Small Globe Valve vom Fachmann

Forged Small Globe Valves sind metallisch dichtend und für hohe Temperaturen geeignet. Optional ist eine Auftragsschweißung (Stellit) zur Lebensdauerverlängerung erhältlich. Die Ventile gibt es mit Flansch-, Einschweiß- oder Anschweißende, aus Stahl oder Edelstahl. Für hohe Druckstufen empfehlen wir die selbstdichtende Pressure Seal-Ausführung zur Minimierung von Leckagen. Alle Globe Valves besitzen keine eigene Zündquelle und sind für geschützte Bereiche geeignet.

Die von Häger Industriearmaturen angebotenen Forged Small Gate Valves können optional mit folgendem Zubehör ausgeliefert werden.

- ATEX Erklärung

- NACE Erklärung

- RF ASME B16.5 , Schweißende

- TA LUFT

- Regulierkegel

Die wichtigsten Eigenschaften von Globe Valves

Unsere vielseitigen Globe Valves ermöglichen eine präzise Steuerung und Absperrung von Flüssigkeiten in Rohrleitungen, eignen sich für Wasser, Gas, Öl, Dampf und andere Medien, und bieten dank optionalem By-Pass-Ventil eine erleichterte Druckregulierung – ideal für industrielle Anwendungen mit hohen Anforderungen an Kontrolle, Temperatur- und Druckbeständigkeit.

Vorteile von Globe Valves

✓ Gute Abschaltfähigkeit.

✓ Moderate bis gute Throttling-Fähigkeit.

✓ Kürzerer Hub (im Vergleich zu einem Absperrschieber).

✓ Erhältlich in T-, Y- und Wye Pattern Typ, die jeweils einzigartige Fähigkeiten bieten.

✓ Leicht zu bearbeiten oder die Sitze neu zu schleifen.

✓ Wenn die Scheibe nicht an der Spindel befestigt ist, kann das Ventil als Rückschlagventil verwendet werden.

Nachteile von Globe Valves

✓ Höherer Druckverlust (im Vergleich zu einem Absperrschieber).

✓ Benötigt größere Kraft oder einen größeren Stellantrieb, um das Ventil zu öffnen (mit Druck unter dem Sitz).

✓ Drosselung unter dem Sitz und Absperrung über den Sitz.

T-Pattern Globe Valve | Durchgangsventil

Der am häufigsten verwendete Globe Valve Typ ist das T-Pattern bzw. Durchgangsventil mit einem Z-förmigen Gehäuse. Die horizontale Lage des Sitzes ermöglicht es der Spindel und dem Kegel sich senkrecht zur horizontalen Linie zu Bewegen. Diese Konstruktion hat den niedrigsten Durchflusskoeffizienten, dafür einen höheren Druckabfall.

Angle Pattern Globe Valve | Eckventil

Diese Art von Globe Valve ist eine Modifikation zum T-Pattern Typ. Die Flanschanschlüsse liegen in einem Winkel von 90 Grad, und der Flüssigkeitsfluss erfolgt mit einer einzigen 90 Grad Drehung. Der Durchflusskoeffizient ist etwas geringer als bei T-Pattern Globe Valves. Hauptsächlich werden diese Ventile in Anwendungen mit pulsierendem Durchfluss verwendet.

Wye Pattern Globe Valves | Schrägsitzventil

Wye Pattern Ventile sind eine alternative für Ventile mit einem hohen Druckverlust. Sitz und Spindel sind um etwa 45 Grad angewinkelt. Dies ergibt einen geradlinigen Strömungsweg bei Offenstellung, und bietet einen geringeren Strömungswiderstand. Häufige werden diese Ventile zum Drosseln verwendet.

Typische Anwendungen von Globe Valves

✓ Kühlwassersysteme, bei denen der Durchfluss reguliert werden muss.

✓ Heizölsystem, bei dem der Durchfluss reguliert wird und Dichtheit von Bedeutung ist.

✓ High-Point-Entlüftungen und Low-Point-Abläufe, wenn Dichtheit und Sicherheit im Mittelpunkt stehen.

✓ Speisewasser-, Chemikalien-, Kondensatabluft- und Absauganlagen.

✓ Kesselschlitze und -abläufe, Hauptdampfabzüge, sowie Heizungsabläufe.

✓ Turbinenabdichtungen und -abläufe.

✓ Turbinenschmierölsystem und andere.